Green Transformation Solutions History

This timeline outlines the development of Shimadzu's Green transformation solutions products over the past 150 years. Each entry reflects Shimadzu's commitment to advancing sensitivity, speed, and usability in analytical chemistry. From the introduction of the first Green transformation solutions systems to the latest innovations, Shimadzu has made significant contributions to various fields, including pharmaceutical research, proteomics, and environmental analysis.

In late 19th century, Genzo Shimadzu Jr., the Japanese Edison, realized the importance of domestic production of storage batteries and began to produce them. His work was successful with the first 10 A lead battery ever produce in Japan in 1897 and called "GS Battery" after his initials. After a long and successful story, his heir is still living on in today's GS Yuasa International Ltd.

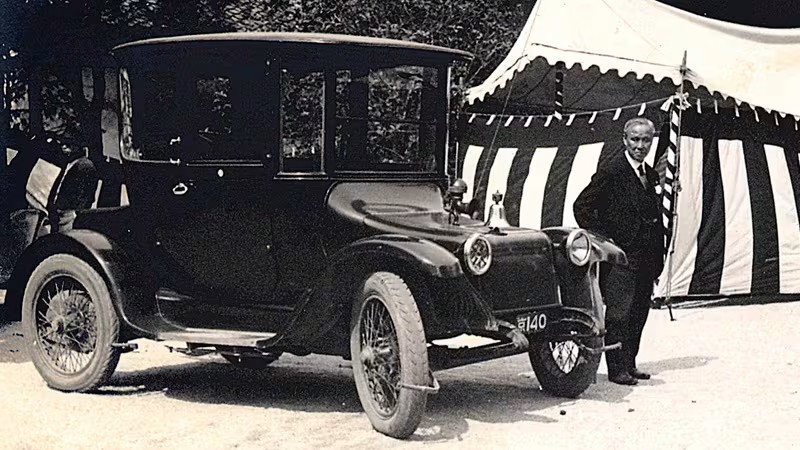

Genzo Shimadzu Junior preferred to drive a Detroit electric car imported from the U.S. about 100 years ago. He equipped this Detroit vehicle with his GS battery and used it to commute to work. Known as Genzo's silk hat because of its shape, it was the focus of interest for the people of Kyoto. In advance in his time, he was convinced of the interest of Electrical Vehicle more than one century that it enter in our daily life.

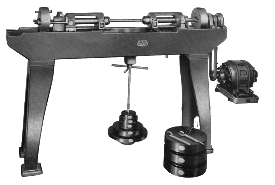

Development of the Ono-type rotating bending fatigue testing machine to perform four-point bending fatigue testing, where the specimen is supported at two points and loaded at two points. Testing, Understand materials performances are the key to develop new composites for hydrogen storage or to analyze materials of a battery.

In 1952, Shimadzu completed the first UV-Vis spectrophotometer system, the QB-50. The system used a crystal prism as a spectroscopic element and was the first UV-Vis spectrophotometer in the world with a photomultiplier tube used as the detector. UV-Vis spectrometers are fundamental to understand interaction between light and materials as, for example, for photovoltaic materials design.

Just four years after the invention of gas chromatography in 1952, Shimadzu developed the first gas chromatograph, leading to the series production of the GC-1A in 1957. Weighing 120 kg, the GC-1A was a giant compared to the more compact and versatile GC instruments that followed over the decades. This innovation initiated a continuous development process that remains active today and contribute to a lot of different applications including Carbon Capture, analysis of battery electrolytes or purity of biofuels.

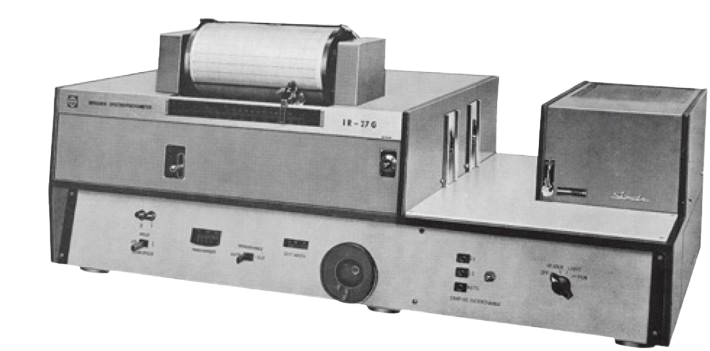

The IR-27G was the 1st infrared spectrophotometer developed by Shimadzu that used diffraction gratings for the diffraction element, and represented a substantial improvement in terms of instrument maintenance. FTIR are keys to understand electrolytes ageing inside batteries for example.

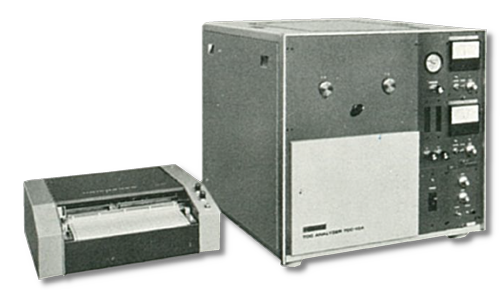

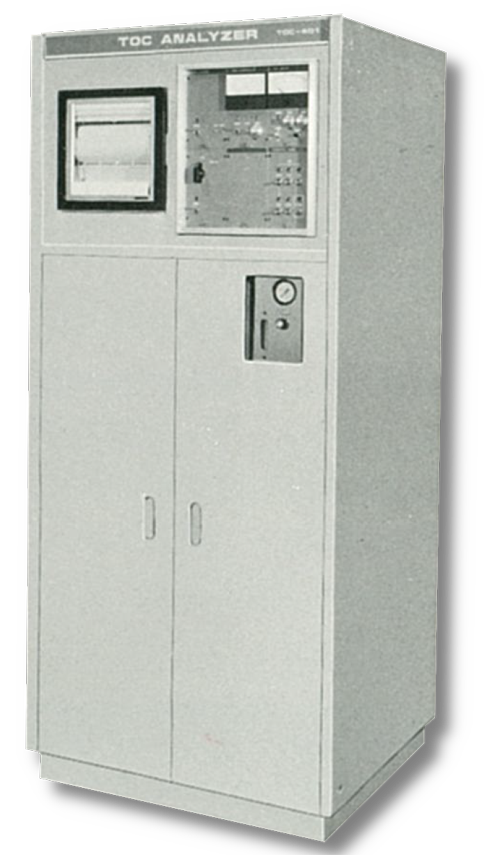

Shimadzu released its first TOC analyzers in Japan: the TOC-100 for continuous water quality monitoring and the TOC-10 for lab use. The TOC-100 was quickly improved, leading to the TOC-100A release the same year. As they can provide a fast and complete analysis of organic contaminants inside water, they are the perfect tools to protect the environment.

After releasing its first TOC products, Shimadzu rapidly improved them, launching the TOC-401, TOC-402, and TOC-10A the next year. TOC-10A allowed manual injection into a 950°C furnace, with CO2 peaks printed and measured by peak height.

Understanding that create an environmental policy will become fundamental for all economic actors and industrial producers, Shimadzu decided to establish very early its own internal service in charge of Environmental Preservation.

Shimadzu's first GC/MS system, the GCMS-6020, combined gas chromatography with mass spectrometry, allowing for improved identification and quantification of organic compounds.

Shimadzu released its first thermospray-based LC-MS product. Thermospray became the most popular interface for LC-MS systems in the 1990s.

Thank to its environmental internal policies and technologies development, Shimadzu received the 10th Global Environment Award-Commendation by the Minister of Education, Culture, Sports, Science and Technology and the he 10th Nikkei Global Environment Technology Award.

Following the construction of our new Head Office building in 2014, Shimadzu planted approximately 1,000 plants created a 8,000m2 Shimadzu Forest was created in the Sanjo Works in Kyoto (Japan).

In 2015 Shimadzu became thus the first manufacturing company in western Japan to win the maximum AAA rating awarded by the Ecosystem Conservation Society-Japan under the Japan Habitat Evaluation & Certification Program (JHEP), a system that objectively evaluates and certifies efforts to conserve and restore biodiversity. The certification was renewed in 2020 and, we maintained our AAA rating.

The Nexera UC supercritical fluid chromatography system represents Shimadzu's commitment to adapting the SFC technology for a broader market. This innovative system seamlessly integrates SFC and LC, providing tailored solutions for pharmaceutical, chemical, and food applications. With patented BPR technology, it delivers exceptional accuracy and reproducibility. The Nexera UC offers faster flow rates and higher throughput using an eco-friendly, low-viscosity mobile phase. Its automated method scouting workflow simplifies method screening, making it an essential tool for achieving high sensitivity and efficiency in challenging separations.

Since 2010, Shimadzu worked on its instruments design in order to reduce their impact on environment during their full life, from the manufacturing to the daily use in the laboratories. In 2017, Shimadzu launched a new certification called "Eco-Products Plus". Shimadzu’s Eco-Products Plus reduces energy usage, saves time on energy-intensive tasks, and minimizes downtime to lower the cost of analysis. These certified models deliver outstanding high environmental performance. Specifically, they achieve at least 25% reduction in at least one of the following criteria compared to the previous models.

In a world’s first, Shimadzu Corporation is adopting a cellulose fiber reinforced flame resistant composite resin, a functional, environmentally friendly material, for our analytical and measuring instruments. This sustainable materials based on GREEN CHIP CMF thereby limiting the use of petroleum derived resins, leading to a reduction in CO2. Because of its high strength, components can be molded more thinly, reducing the weight of products. Moreover, this composite materials is specifically designed with a high resistance to flame. The materials is used in the configuration units of 15 models in the Nexera series.

All bags used to package accessories for the Nexera series ultra high performance liquid chromatograph systems have been changed to biomass plastic bags. These are made from 30 % “green polyethylene,” a plant-based plastic. Biomass plastic not only reduces the amount of petroleum-based plastic used but also reduces CO2 gas through the photosynthesis process where the growth of its main ingredient, sugar cane, increases.

On October 21, 2020, the Minister of the Environment designated Shimadzu as an 'Eco-First Company'. This is the first time in the precision equipment industry.

Based on the “Eco First Program”, the Ministry of the Environment certifies the companies that promise to engage in environmental conservation initiatives that are ”innovative, unique and spillover effects” and that are carrying out industry-leading activities.

Shimadzu Corporation has joined RE100, a global environmental initiative, and pledged that the Shimadzu Group would use 100 % renewable energy in its business activities by 2050. Consequently, in addition to the Head Office/Sanjo Works and Murasakino Works in Kyoto, solar panels have been installed at Group companies in Shimane in Japan, Malaysia, and the Philippines to generate electricity for their own use. Group companies in Germany and the U.K. have switched to electricity contracts that provide 100% renewable energy.

The energy-saving design of the Brevis GC-2050 reduces power consumption by 30% compared to conventional models even during normal operation. Furthermore, the new ECO Idling function reduces power consumption by approximately 61% and gas consumption by 92% compared to conventional models. The power savings can be converted into a CO2 reduction equivalent to the annual CO2 absorption of 86 cedar trees per unit.

GC-2050 is the World's First Gas Chromatograph (GC) Systems with CO2 Reduction Visualization Function. The amount of CO2 reduction and the savings in power, gas, and cost can also be viewed on the software screen which raises operator awareness of savings and makes the lab more eco-friendly.

Shimadzu Corporation received the SDGs Strategy/Economic Value Award at the 6th Nikkei SDGs Management Awards. Nikkei SDGs Management Awards recognize advanced companies that have both contributed to the Sustainable Development Goals (SDGs) set by the United Nations and enhanced corporate value through their business. Shimadzu is highly regarded in the category of SDGs Management in the fields of SDGs Strategy/Economic Value and Environmental Value, and we acquired the highest “★★★★★” ranking.

In April 2024, Shimadzu launched the ELEM-SPOT system, the world's first element-selective gas chromatograph mass spectrometer - which enables the detection of oxygen - and nitrogen - containing components. This system is the first in the world capable of selectively detecting only the oxygen - and nitrogen - containing components that affect the quality of biofuels, from among the multitude of constituents present in raw materials. ELEM-SPOT was co-devloped by Shimadzu, Total Energies SE, the University of Pau (France) and the University of Oviedo (Spain).

Shimadzu has been awarded a ‘Bronze’ rating in a sustainability survey conducted by EcoVadis (headquartered in France), which conducts extensive surveys and assessments of over 90,000 suppliers around the world in the areas of Environment, Labor and Human Rights, Ethics, and Sustainable Procurement of Materials.

First in the MALDI-TOF MS Sector, Shimadzu earns My Green Lab® ACT® Ecolabel Certification for MALDI-8000 Series Mass Spectrometers. This certification underscores our commitment to sustainability and environmental responsibility in scientific research and laboratory practices. Key sustainability features of our MALDI-8000 series MALDI-TOF Mass Spectrometers, as verified by the ACT certification, include:

1) Energy Efficiency: Designed to lower the carbon footprint of your laboratory operations, with the total energy consumption under typical use case of about 4.6 kWh per day.

2) Waste Reduction: Compared to previous products, there has been significant dematerialization of nearly 75% by weight, to minimize hazardous waste production.

3) Use of Sustainable Materials: The product and packaging are composed almost entirely of readily recyclable materials.

Throughout its 150-year history, Shimadzu has gathered numerous stories that exemplify its role in the advancement of analytical technology. Each narrative reflects the contributions of individuals and the evolution of innovations across various fields. Below, we present some of these stories that highlight key milestones in our journey and the impact they have had.

Photovoltaics is an important pillar of the energy revolution and is more topical than ever before as a research field. Classic rigid silicon solar cells have long been part of everyday life – from pocket calculators to large solar modules in private homes and industrial solar parks. In the future, flexible or even transparent solar cells made from organic materials could enable an even wider range of applications. The development of high-performance UV-Vis spectrometers is valuable for identifying and testing materials or cell prototypes and paves the way to technically sophisticated products. Explore how the Shimadzu UV-3600i Plus will support the development of new organic photovoltaic materials.

A significant part of battery aging can be considered as a result of the decomposition of the electrolyte. The electrolyte solution is a crucial part of a typical lithium-ion battery (LIB), consisting of Li salt (e.g. LiPF6), organic carbonates and additives to ensure a stable transport of Li ions during charging and discharging processes.Charge/discharge cycles alterate the electrolyte and decomposition products will reduce batteries performances and can even be the origin of a complete failure. With the GCMS-2030, a simple and reliable method make you able to identify early signs of destruction.

At Wild Hydrogen, we are developing and optimising an innovative reactor technology to produce carbon negative hydrogen from wet biogenic materials. Precision and accuracy are crucial to their process, which is why they rely on Shimadzu’s instrumentation. and more specifically Shimadzu GCMS-QP2020 NX to analyse the gases, liquids, and solid residues produced during their trials. This system allows them to efficiently determine gas composition, monitor by-products, and ensure consistent performance as they push the boundaries of sustainable energy production.

The flexibility and robustness of Shimadzu’s solutions have been key to maintaining the accuracy and reliability of their data, allowing them to refine our technology faster.

By enabling rapid, high-precision analysis, Shimadzu’s equipment helps them make data-driven decisions that are

critical to achieving their mission: making carbon-negative hydrogen and biomethane the affordable fuel of the

future and helping to decarbonise heavy industry.

Are you interested in our Green Transformation Solutions? You can explore them up close at various upcoming events. Our experts will be available to answer any questions you may have. We look forward to seeing you there!

ELEM-SPOT

Shimadzu’s unique ELEM-SPOT system is the world’s first Gas Chromatograph Mass Spectrometer (GC-MS) with an element-selective combustion unit (EL-30) included for selectively analyzing nitrogen-containing compounds or oxygenated compounds in complex hydrocarbon compounds with high sensitivity.

UV-1900i

Shimadzu can provide a comprehensive suite of instruments used for hydrogen quality control, analysis of catalysts and water for electrolysis, and evaluation of fuel cells and their components.

Lithium-ion Batteries

Shimadzu offers a variety of analytical and measuring instruments for lithium-ion battery applications ranging from R&D and evaluation of material characteristics to product quality control, degradation analysis, and recycled material evaluation. We are committed to achieving a sustainable society by offering optimal solutions for customers involved in all life cycle stages of lithium-ion batteries.