Textiles/Fibers Materials Testing

Testing, Analysis and Inspection of Textiles and Fibers

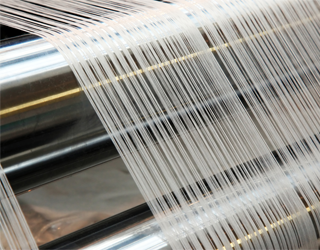

Shimadzu offers a wide range of instrumentation to support the evaluation of textile products, including fabric, cord, webbing, yarn, tow, and fibers. High-precision mechanical test frames can be used to accurately measure force and elongation in conjunction with our large selection of grips and accessories, which can be easily swapped out to perform peel, grab, tear, and puncture tests. Pneumatic grips are available with flat, serrated, rubber-coated, and wave grip faces, and various capstan, split drum, and roller grips are available to accommodate many different sample types, such as geotextiles, nonwovens, belts, webbing, leather, wire, and composite fibers. Shimadzu’s extensive lines of analytical instrumentation offers complimentary analysis capabilities for the chemical and thermal analysis of textiles.

Featured Applications

Tensile Test of Fabrics (JIS L 1096 Strip Method)

Various types of performance are required in clothing, depending on which value that the wearer prioritizes, e.g. comfort, functionality, or design, and new products are appearing daily to meet these needs. Since clothing is a product, strength evaluation is necessary in order to maintain a certain quality. JIS L 1096 : 2010 not only provides methods for measuring the tensile strength and tear strength of the woven and knitted fabrics that are indispensable in our daily lives, but also describes various evaluation methods for the permeability of fabrics to air and their heat-retaining property. Among these, the JIS and ISO methods include a total of 6 test methods for tensile strength. There are 4 JIS methods, method A (strip method), method B (grab method), method C (wet strip method), and method D (wet grab method), and 2 ISO methods, method E (strip method) and method F (grab method). This article introduces an example of a tensile test of fabric specimens by method A (strip method).

Analysis of Perfluorooctane Sulfonamidoethanols and Fluorotelomor Alcohols in Textiles

Perfluorinated compounds (PFCs) represent a large collective of chemicals, which have been used widely in textile, leather and other consumer products for their unique water and oil repellent properties. However, PFCs including PFAS (per- and polyfluoroalkyl substnaces) also become environmental and health concerns. Some components like perfluorooctanesulfonic acids (PFOS) and perfluorooctanoic acid (PFOA) are regulated as restricted substances in textiles by industrial standards and regulations. LC/MS/MS and GC/MS have been used in analyses of various PFCs or PFAS in various environmental samples and consumer products. Perfluorooctane sulfonamidoethanols (FOSEs) and flurotelomer alcoholcs (FTOHs) belong to less-polar PFCs and may degrade to form PFOS and PFOA. Normally, they are analyzed using GC/MS with chemical ionization (CI) due to their non-polar properties. In this study, an alternative method using LC/MS/MS was developed for the analysis of four FTOHs and two FOSEs in textiles to respond to the recent demands in testing analysis for textile and consumer products.

High-Speed Tensile Testing and Observation of Polypropylene Fibers

In the world of synthetic fibers, product research is being actively pursued to improve performance, such that products with enhanced functionality (such as superior strength and resistance characteristics) are now being used in a variety of fields. In particular, the automotive and aerospace fields have shown interest in the flexibility and light weight characteristics of fibers and have been increasing their applications. However, at the same time, in terms of strength, it is now necessary to determine not only static limit values, but characteristics under high-speed loading (or impact) conditions as well. As an example of such testing, a tensile test was performed on polypropylene fiber using a HITS-X Series High Speed Impact Testing Machines, capable of tensile testing at loading rates of up to 20 m/s, with grips designed for tensile testing fibers attached.

Tensile Test on Carbon Fibers (Reference Standards: ISO 11566:1996 / JIS R 7606:2000)

Mobile products require the strength to resist bends, drops and other external forces, and any glass pieces must also be sufficiently strong. For glass, there are typically two types of strength, which are measured by different methods. One type is edge strength, which is obtained from 3-point (or 4-point) bending tests. The other type is surface strength, which is determined from ring bending tests. In this method, fracture starts near the center of the glass, so there is no cut surface impact. In other words, surface strength could be called an indicator of the strength of the glass surface itself. In this article, we introduce an example of a ring bending test, as per the ASTM standard, to obtain the surface strength of glass.

Evaluation of Endurance Characteristics of Synthetic Thread (Micro-Servo)

Recent improvements in the performance of synthetic fibers have been remarkable, helping to produce new lightweight, tough, and high-strength synthetic fiber products. They are being applied in a wide range of fields, including new material development in aerospace fields and consumer products in the everyday household product fields. Tensile tests and cyclic loading tests of synthetic thread are essential for synthetic fiber (synthetic thread) development.

A Fast LC/MS/MS Method for High Sensitivity Determination of Twenty-Six Perfluorocompounds in Textiles

Perfluorocompounds (PFCs) are widely used in different consumer products including textile coatings for their excellent oil and water repellent property. However, researches in recent years have shown that PFCs can cause adverse effects to organisms and being persistent in both environment and organism. Hence, industries started to phase out the use of PFCs 2000. The European Union (EU) had announced a maximum level of 1 µg/m2 for PFOS while for Norway, a maximum level of 1 µg/m2 for PFOA. Hence, there is a need for quantitative analysis of extractable PFOS, PFOA and other PFCs in various skin-contact consumer products like textiles. Here, we describe a fast LC/MS/MS method for high sensitivity screening and quantitation of 26 PFCs in textiles on Shimadzu LCMS-8050.